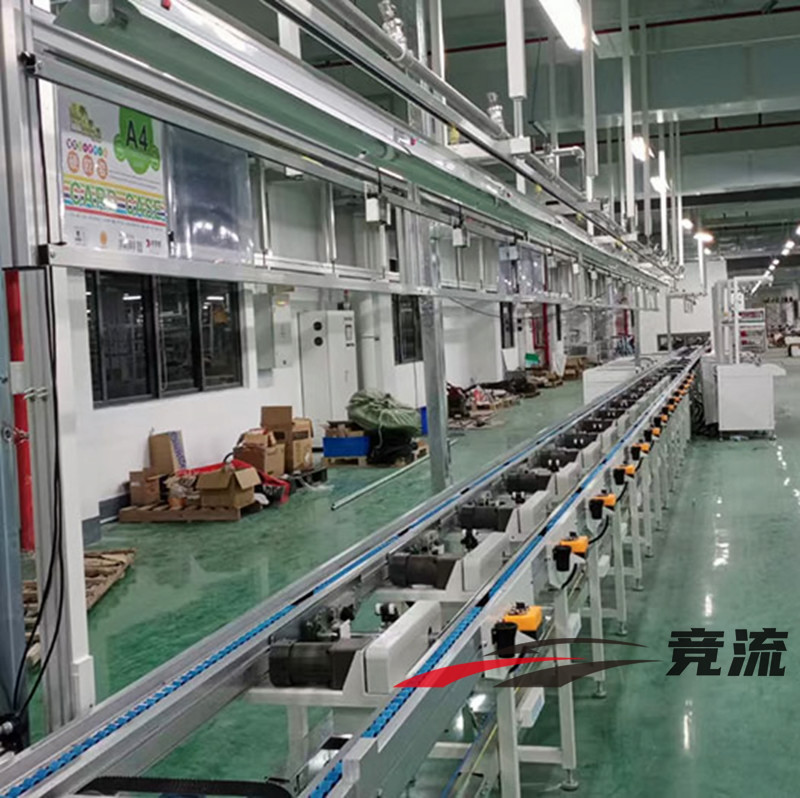

Inverter production line

summary:

The essence of the inverter is a "power converter", but its role goes far beyond the simple "DC to AC"-it solves the intermittent nature of new energy power generation through intelligent control, grid adaptation, energy management and other technologies. Key issues such as the bi-directional nature of the energy storage system and the power demand of electric vehicles are one of the core equipment supporting the energy transformation under the "double carbon" goal (from fossil energy to renewable energy, from centralized power supply to distributed power supply).

Core equipment (such as photovoltaic panels and wind turbines) used for power generation from renewable sources such as solar energy and wind energy all outputs DC power, but the power grid and most electrical equipment (such as home appliances and industrial motors) require AC power. In this scenario, the inverter undertakes the dual functions of "energy conversion + grid adaptation":

1. Photovoltaic power generation system:

DC to AC: Solar panels generate DC electricity through the photovoltaic effect, and inverters convert it into AC that meets grid standards.

Power grid adaptation: The inverter needs to synchronize the frequency, phase and voltage of the power grid to ensure that the output AC power is "at the same frequency and phase" with the power grid in order to be connected safely.

Maximum Power Point Tracking (MPPT): The output power of the photovoltaic panel is affected by light and temperature (such as voltage reduction on rainy days). The inverter adjusts the input voltage in real time through the MPPT algorithm, so that the photovoltaic panel always works at the point of maximum power, improving power generation efficiency.

2. Wind power generation system: The output of the wind turbine is also DC (or converted to DC through a rectifier). The inverter needs to convert it into stable AC power and adjust the output frequency according to changes in wind speed to ensure that the grid-connected current meets the requirements of the power grid.

In the energy storage scenario, the battery stores DC power, but the electrical equipment requires AC power, and the energy storage system often needs to "work in both directions of charge and discharge." At this point, the bidirectional inverter (or PCS, power conversion system) plays a key role:

1. Discharge mode (battery → load/grid)

The DC power of the battery is converted into AC power through an inverter for use in homes, factories or power grids (for example, the household energy storage system supplies power to refrigerators and air conditioners during power outages; the grid-side energy storage transmits power to the power grid during peak power consumption).

2. Charging mode (grid/load → battery)

When grid electricity prices are low or photovoltaic power generation is excessive, the inverter works in reverse to convert AC power into DC power to charge the battery (i.e., the "rectification" function).

3. energy management

Modern bidirectional inverters integrate intelligent control modules that can automatically adjust charging and discharging strategies (such as "peak-valley arbitrage") based on electricity prices, load demand, and battery remaining capacity (SOC) to maximize the economy of the energy storage system.

Our inverter production line uses conveyor belt assembly line operation and is equipped with automated equipment such as mount machines (SMT), plug-in machines, welding robots, and automatic screw locking machines to realize the whole process from circuit board mounting, component welding to complete assembly. Operation. Unmanned or less-human operations reduce errors and efficiency losses caused by manual intervention. Combine lean 5S management and digital traceability system to eliminate waste, strictly control quality, and integrate AI algorithms and information technology to achieve environmental safety control and intelligent optimization of process parameters, ultimately forming an intelligent manufacturing advantage of "high efficiency, high precision, and high flexibility"., significantly enhance market competitiveness!

Send Inquiry